Scales are normally used to weigh a certain about or product into the package. There are a variety of scale designs, but we will simplify it into linear scales and rotary scales. Some scales can be used to count the appropriate number of items into a package. This works well when the pieces are relatively consistent in weight. More information on this can be found on the counting page.

Scaling Systems

Linear Scales

Linear scales can be simple with a hopper to hold product while a vibratory feeder moves product into a second hopper which attached to a load cell. The load cell tells the vibratory feeder unit to slow down as the target weight approaches and turns it off when the target weight is reached. The second hopper containing the product is opened by triggering a switch. This releases the product down a chute and into the desired package. Many variants of this principle can be employed to handle different types of products. Combined hoppers and feeders can be employed to maximize speed and accuracy. Using multiple load cells increases the speed. High-capacity components can be used for target weights up to 100-pounds. Linear scales are very common in small and mid-sized manufacturing, and when the loads are larger.

Linear Scale

Rotary Scales

Rotary scales are also referred to as combination scales. The term refers to the fact that by using multiple buckets attached to load cells to hold product, a PLC can choose a combination of the buckets to create the target weight. At the risk of oversimplification, the product is distributed into multiple buckets. Each bucket is on a load cell around the circumference of a circle. A rotary scale will typically have 10 to 32 buckets in the equipment. There are many options for the number of bucket used, and volume of the buckets in a scaling system. Finding the right scale set is determined by examining the product and other parameters during a product review. By finding the right configuration, the delivered weights can be precise and at speeds over 100 packages per minute.

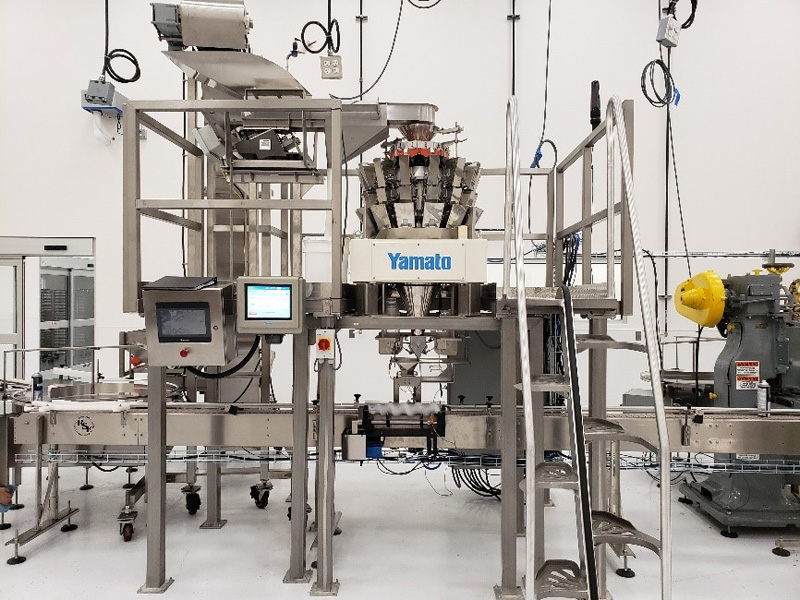

Rotary Scale

The scales are typically used to deliver the product to a packaging system below. The packaging system can be designed to fill including jars, bottles, flexible packaging, cases, clamshells, and more.

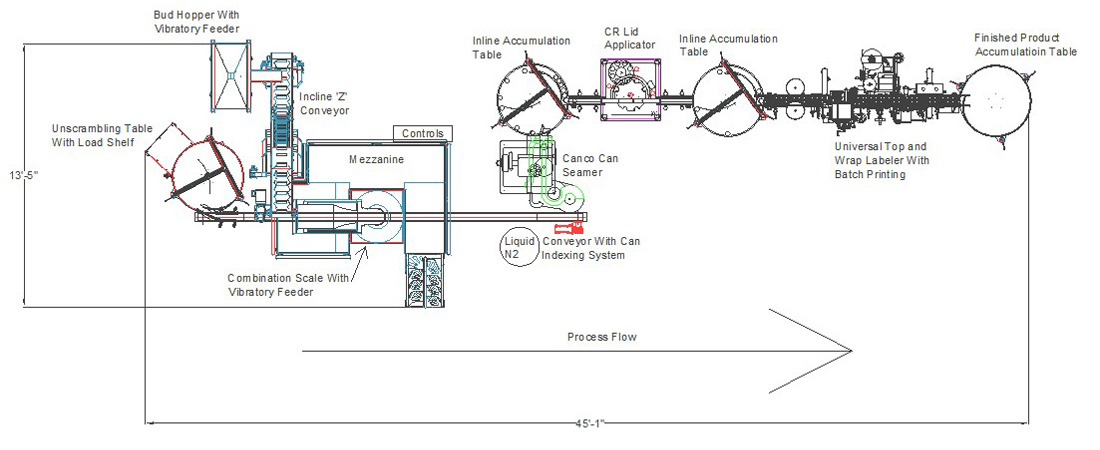

Scales are often part of an integrated system for automatic packaging mounted over a VFFS or HFFS. These automated packaging systems are very common in food manufacturing and typically include equipment listed below to create an automated packaging line:

Feeders: Meter the product evenly to the scale. These include vibratory feeders, bucket elevators, incline conveyors, pneumatic transfers, screw conveyors and more.

HFFS/VFFS are the often the machines the scales drop the product into.

Coding: Lot codes and expiration dates are commonly required on the package and the coders are incorporated into the packaging line. There are many types of coders to choose from.

Inspection: Many products require inspection after the product is securely in the primary package. Inspection methods include metal detection, check weigh, X-ray or vision to identify products or packaging that does not meet quality standards.

Structure: Scales need to be elevated and that means it is mounted on some type of structure. These are typically an independent stand or combined with the mezzanine.

Robotic Palletizing: Automated palletizing is often found at the end of the line.

Considering your options for scaling systems? Contact RSE at 303.327.4704, or Email Us for more information.