Depal FA

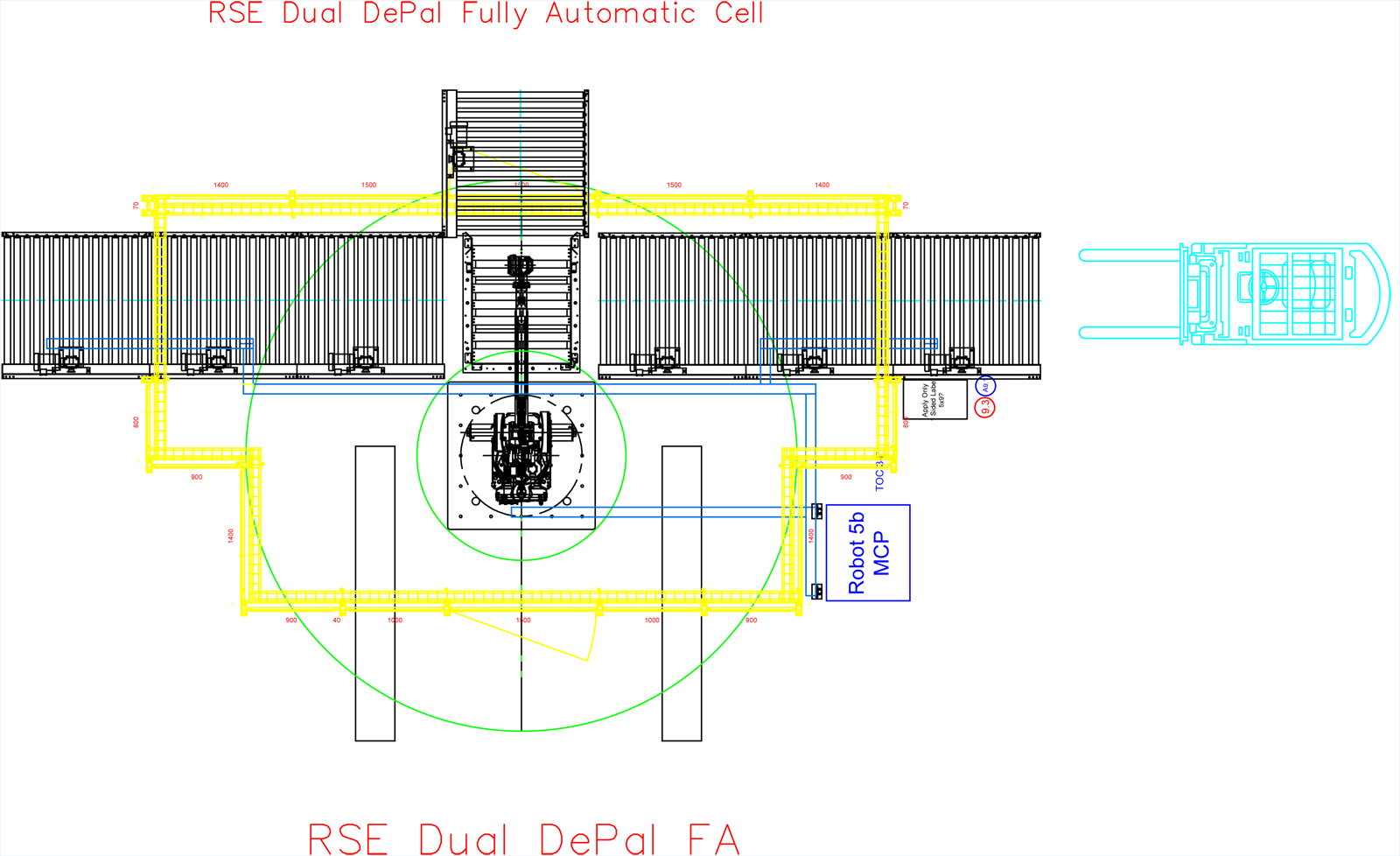

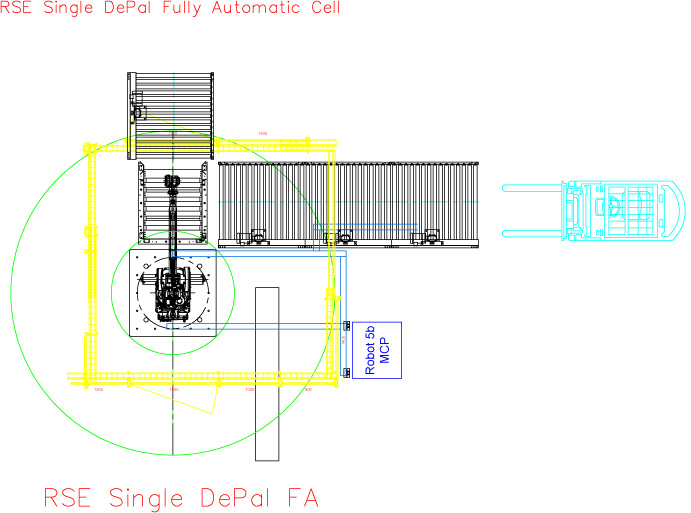

The Automatic Depalletizing Cell is designed for the mid-sized and large companies which receive containers on a pallet which need to be depalletized and placed onto a conveyor for further filling, handling or processing. The single robot can run up to 14 cycles or picks per minute while the number of pieces to be picked per cycle is project dependent. The pallet conveyor is loaded via forklift with the product to be depalletized. The pallet is loaded onto a roller conveyor and indexed automatically into its pick position. A light source and vision system ensure that the robot is picking the product properly and placing it accurately while a light curtain set that act as a safety system. Light curtains and interlocks on doors prevent a person from entering the cell which the robot is operational. The cell can include one or two pallet infeed conveyors. Once a package is in position, a sensor will communicate to the robot that the package is ready to be picked. After the pallet is cleared, it will exit the depalletizing cell to be picked by a forklift operator or indexed into a pallet stacker.

An indicator light will indicate an operational status to the operator from a distance.

The HMI has a color 10” screen which is intuitive and easy to follow, with three levels of access for the operator, maintenance, and engineer levels. The HMI will provide details on each fault and steps to clear them. The HMI also contains a manual, schematics to facilitate maintenance and engineering when needed. The Alan Bradley PLC controls the entire system while the HMI provides an intuitive set of screens to run the palletizing cell. The EOAT is specific to the type of package to be loaded.

The Fanuc Multi Axis Robot Arm has capacity of 140 kg (308#) is the capacity of a maximum weight per pick including the End Of Arm Tool (EOAT).

Option Packages include:

- Specific EOAT Required

- Automatic Slip Sheet Removal

- Heavy Duty Robot with 180kg Capacity

- Automatic Pallet Stacker