Four-sided Pouch Packaging Automation

Integrated pouch equipment packaging will normally incorporate additional equipment to create a turn-key packaging line. Right Stuff Equipment can provide the turnkey system for your facility. Email or call us at 303-327-4704.

Marking and Coding: Incorporated into the filler or executed immediately after the filler to track lot numbers, batch codes and expiration dated. Also used increasingly for track and trace requirements that are becoming more popular. A variety of coding options are available. CIJ, Thermal Transfer, HP, Dot Matrix, Hot Wax, Labeling and Embossing all have their place in packaging automation to identify and code products. Right Stuff Equipment will help you identify the right identification system for your application.

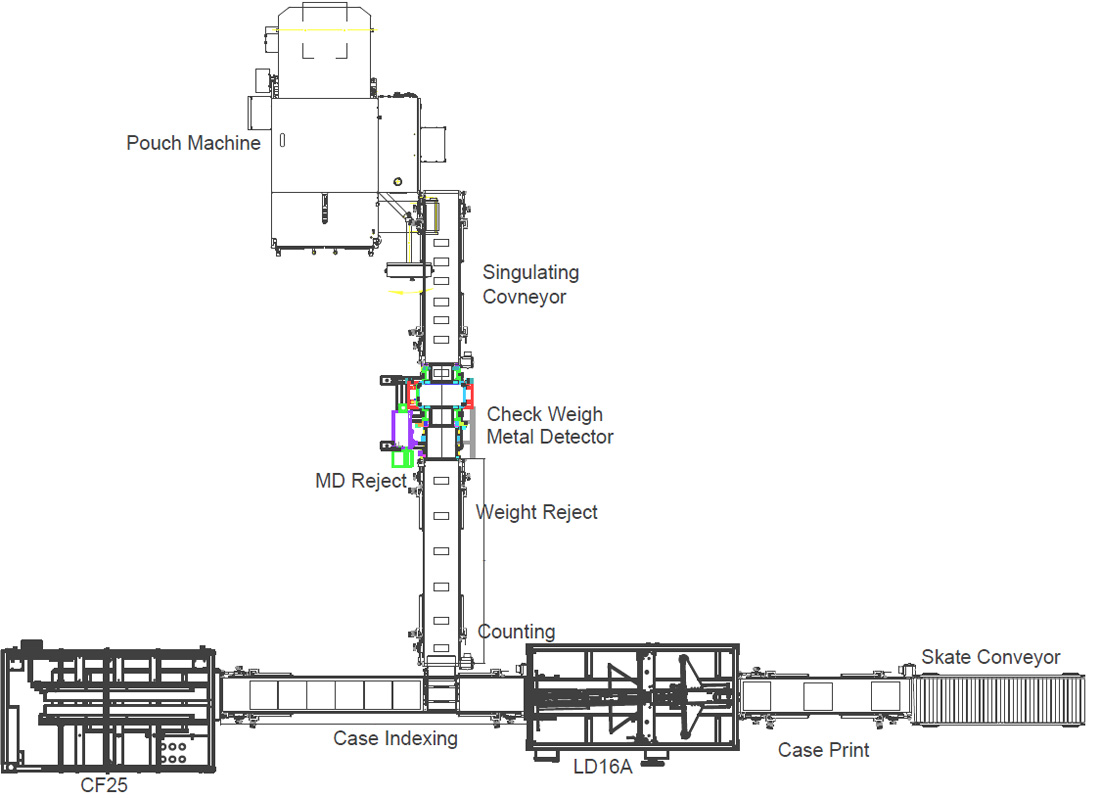

Inspection: These can include metal detection, check weigh, X-ray or vision to identify products or packaging that does not meet quality standards. Many of the larger retailers are requiring X-ray inspection for food products. A letter from Costco is a prominent example.

Structures: Many flexible film automated packaging systems will require a structure of some type. Machine stands, platforms and mezzanines are common.

Feeders: There are many feeders for pouch packaging equipment. Auger feeders, bucket elevators, incline conveyors, pneumatic conveyors are all used to deliver the product to the filler that then delivers the right amount of product to the flexible film packaging machine.

Product Fillers: There are many feeders for pouch packaging equipment. Auger fillers, liquid fillers, scales, counters are common fillers used to deposit the product into the flexible film package.

Cartoning equipment and Case Packing equipment: Usually consists of loading the pieces into cartons or master cases.

Robotic Palletizing: Robots have taken a large part of the palletizing automation market share. The advantages include reliability, performance and competitive pricing.