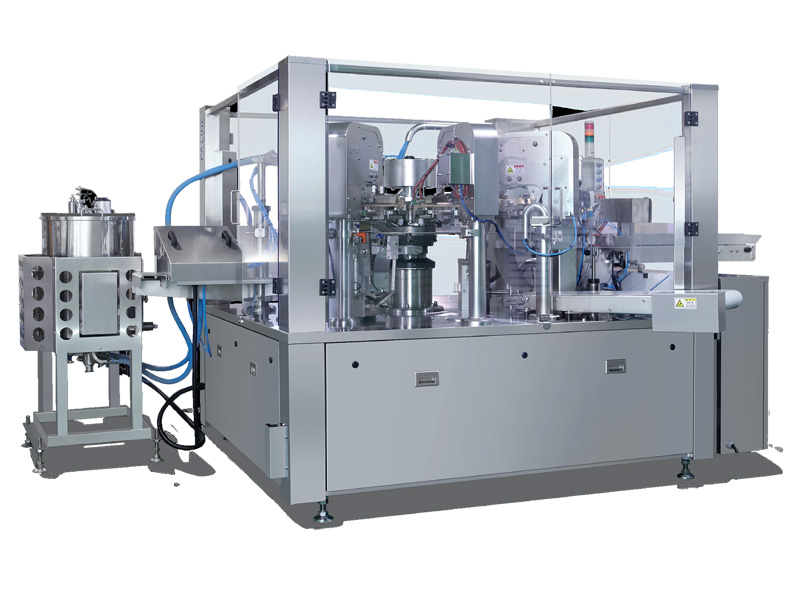

Premade Pouch Machines are often called PMP machines. They use premade pouches instead of roll stock film to create the product. This equipment uses pouches that have been formed on another machine with one end open so the product can be inserted into a feeder which loads them into the machine for filling and sealing. Solids, liquids and powders are all routinely filled and again may have more than one compartment within the pouch for multiple ingredients. The machines can also be built to fill more than one pouch per cycle.

Premade Pouching Machines

A PMP machine offers several advantages compared to other packaging solutions. Here are some key benefits:

Efficiency: Premade pouch machines are designed for high-speed operation, allowing for rapid packaging of products. This efficiency can lead to increased productivity and reduced labor costs.

Consistency and Quality: Since the pouches are produced off site on high speed equipment, they are extremely consistent. This allows the PMP machine to provide consistent sealing and filling, ensuring a uniform appearance and quality of the pouches. This consistency helps in maintaining product integrity and meeting quality standards.

Versatility: Premade pouch machines can handle various pouch types, including stand-up pouches, zip-lock pouches, and flat pouches. This versatility allows manufacturers to switch between different pouch styles with minimal adjustments.

Reduced Material Waste: Since premade pouches are already formed, there is less material waste compared to roll-stock packaging systems, where excess film can be generated during the forming process.

Reduced Setup Time: With premade pouches, there’s no need for extensive setup or changeover processes that are typically required for roll-stock machines. This can lead to faster transitions between different products or pouch sizes.

Enhanced Aesthetics: Premade pouches often come with high-quality, pre-printed designs and finishes, which can enhance the product’s shelf appeal and branding without the need for additional printing equipment.

Less Equipment Wear: Since the pouches are premade, there is less wear and tear on the machine compared to systems that form pouches from film rolls, which can result in lower maintenance costs and longer equipment lifespan.

Easier Integration: Premade pouch machines are often easier to integrate with existing production lines due to their straightforward operation and reduced need for complex adjustments.

Flexibility: These machines can handle various filling techniques, such as liquid, powder, or granular products, making them suitable for a wide range of applications.

Cost-Effective: While the initial investment may be higher, the reduced waste, lower labor costs, and faster setup times can make premade pouch machines a cost-effective solution in the long run.

When considering the purchase of a PMP machine or a turnkey automated pouch line there are some key considerations to review internally and with your integrator.

Key Considerations

Product Type: The machine should be suitable for the type of product being packaged, whether it’s powder, liquid, granules, or solids.

Package Size and Shape: PMP machines can be adjusted to produce various pouch sizes and shapes. Customization options are available for specific packaging needs.

Speed and Efficiency: Consider the required production speed and whether the machine needs to integrate with other systems in the production line.

Film Material: The choice of film material affects the package’s durability, appearance, and sealing properties. The film should be selected based on the product’s requirements and shelf life.

Integration Partner Selection: Finding the right integration partner is a key to success for your packaging automation project. Right Stuff Equipment will help you with the right solution. Contact us or call 303-327-4704.

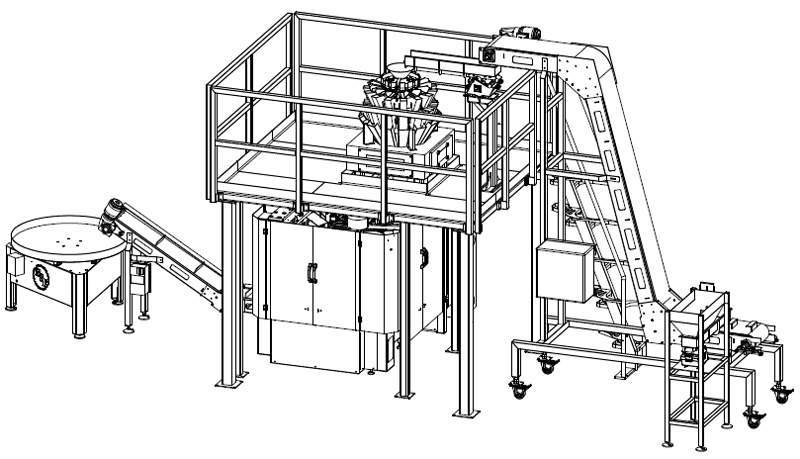

A typical automated pouch packaging line with a PMP machine is shown below with additional equipment before and after the pouch machine. An experienced integrator can help you select the right packaging equipment to deliver a balanced line right for your needs.

Integrated pouch equipment packaging will normally incorporate additional equipment to create a turn-key packaging line. Right Stuff Equipment can provide the turnkey system for your facility. Email or call us at 303-327-4704.

Marking and Coding: Incorporated into the filler or executed immediately after the filler to track lot numbers, batch codes and expiration dated. Also used increasingly for track and trace requirements that are becoming more popular. A variety of coding options are available. CIJ, Thermal Transfer, HP, Dot Matrix, Hot Wax, Labeling and Embossing all have their place in packaging automation to identify and code products. Right Stuff Equipment will help you identify the right identification system for your application.

Inspection: These can include metal detection, check weigh, X-ray or vision to identify products or packaging that does not meet quality standards. Many of the larger retailers are requiring X-ray inspection for food products. A letter from Costco is a prominent example.

Structures: Many flexible film automated packaging systems will require a structure of some type. Machine stands, platforms and mezzanines are common.

Feeders: There are many feeders for flexible film packaging equipment. Auger feeders, bucket elevators, incline conveyors, pneumatic conveyors are all used to deliver the product to the filler that then delivers the right amount of product to the flexible film packaging machine.

Product Fillers: There are many feeders for flexible film packaging equipment. Auger fillers, liquid fillers, scales, counters are common fillers used to deposit the product into the flexible film package.

Cartoning equipment and Case Packing equipment: Usually consists of loading the pieces into cartons or master cases.

Robotic Palletizing: Robots have taken a large part of the palletizing automation market share. The advantages include reliability, performance and competitive pricing.

Considering your options for packaging automation? Contact Right Stuff Equipment at 303.327.4704, or Email Us for more information.