Horizontal form fill and seal machines are often referred to as HFFS machines. HFFS machines come in different styles. Here, we examine HFFS flow wrapper machines.

Flow Wrapper

Flow wrapper machine

As a subset of HFFS machines, flow wrappers are used in packaging automation to enclose products in a sealed film. The largest deployments of these machines are baked goods, candy bars and protein bars. The main function of these machines is to provide a protective, tamper-evident, and often visually appealing package for products. Many flow wrappers have an attached coding machine to place lot code and date code information on the wrapper. Some film wrappers are clear film but often the film has an appealing label and product information pre-printed on the film. The flow wrapper places the product in the film at the correct position by reading an eye mark on the film for film and product alignment. Some machines will also have a sensor for the product and not make a bag if there is no product in a product position. This saves film by using the “no product, no bag feature”. There are a variety of machines with designs to handle different types of products and different capacities. Most machines are continuous motion and will pack form 30 pieces per minute on the low end to over 1,000 pieces per minute. When running high speed production, non heat seal film is usually required.

Some of the considerations to keep in mind when looking at flow wrappers include the min and max size of the product, product size consistency, production rates, hermetic seal requirements, gas flush, film type and more. You should discuss the product and film requirements with a knowledgeable representative or integrator when considering a purchase.

Basic Operation

Film Feed: A roll of packaging film is fed into the machine. This film is typically made of a poly laminate material. Different types of films will require different temperatures and dwell time to get optimal seal. Again, consulting an expert in the field will assure you get the right system.

Infeed: The product is placed on an infeed section which transfers it into the forming area. Infeed systems can consist of hand placing product or an automated infeed set that automatically positions the product info the forming section. The product placement can include moving from multilane product dispenser into single file so they can be spaced into the sealing area.

Forming: The film is unwound and formed into a tubular shape around the product as the film travels through a forming box. Forming boxes can be fixed or adjustable for different sized products. Fixed forming boxes create a consistent set up and reduce change over time. Adjustable forming boxes allow the operator to run a variety of sizes on the same former but require knowledge for the correct set up.

Sealing: The film is sealed around the product, usually through a combination of heat, pressure and dwell time. These three elements can be managed to optimize the film seal. Film quality and composition have a large impact on the quality of film seals as well. Different film construction will also impact the vapor and oxygen barrier properties which may impact the shelf life of your product. You should consult with your film supplier on what is the best type of film for your product and marketing requirements.

Cutting: The sealed film is cut to the desired length with a knife and anvil set which can create different seal patterns and types of cuts to the film.

Types of Packages produced on Flow Wrapper Machines

Pillow Pack Wrappers

Operation: A type of horizontal flow wrapper that creates a simple pillow-shaped package by sealing the film on the sides and ends.

Advantages: Cost-effective and straightforward design. Often used for single-serve products or small items.

Gusseted Flow Wrappers

Operation: These machines create packages with expandable sides, known as gussets, allowing for more space and flexibility in packaging.

Advantages: Useful for packaging bulky or irregularly shaped products. Provides extra room for products and can improve the visual appeal.

Shrink Wrapping Machines

Operation: After the product is wrapped, it is passed through a heat tunnel that shrinks the film tightly around the product.

Advantages: Provides a tight, tamper-evident seal and is suitable for various product sizes and shapes. Often used in conjunction with flow wrappers for added security.

Key Considerations

Product Type and Size: The choice of flow wrapper depends on the product’s size, shape, and packaging requirements.

Speed and Efficiency: Consider the required packaging speed and whether the machine needs to integrate with other production equipment.

Film Type and Material: The type of film used can affect the machine’s performance and the quality of the final package.

Film Material: The choice of film material affects the package’s durability, appearance, and sealing properties. The film should be chosen based on the product’s shelf life and protection needs.

Integration Partner Selection: Finding the right integration partner is a key to success for your packaging automation project. Right Stuff Equipment will help you with the right solution.

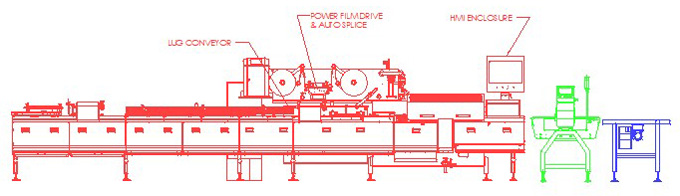

An example of an automated packaging line with a flow wrapper is shown below with additional equipment before and after the flow wrapper. An experienced integrator from Right Stuff Equipment can help you select the right packaging equipment to deliver a balanced line right for your needs. Email or call 303-327-4704.

Integrated flow wrapper machines will normally incorporate additional equipment to create a turn-key packaging line. Right Stuff Equipment can provide the turnkey system for your facility. Email or call us at 303-327-4704.

Marking and Coding: Incorporated into flow wrapper to track lot numbers, batch codes and expiration dates. Codes are used increasingly for track and trace requirements. A variety of coding options are available on flow wrappers. CIJ, Thermal Transfer, and Laser are most common. Right Stuff Equipment will help you identify the right identification system for your application.

Inspection: These can include metal detection, check weigh, X-Ray or vision to identify products or packaging that does not meet quality standards. Many of the larger retailers are requiring X-Ray inspection for food products. A letter from Costco is a prominent example.

Feeders: There are many feeders for flexible film packaging equipment. Sorting equipment, singulation and chicaning conveyors are all used to deliver the product to the wrapper to facilitate high speed flow wrapping when an automated infeed set is included with the flow wrapper.

Cartoning equipment and Case Packing equipment: Usually consists of loading the wrapped pieces into cartons or master cases.

Robotic Palletizing: Robots have taken a large part of the palletizing automation market share. The advantages include reliability, performance and competitive pricing.

Considering your options for packaging automation? Contact Right Stuff Equipment at 303.327.4704, or Email Us for more information.