Counting systems are part of packaging automation. Counting systems include counting pieces into a primary package or packages into master pack. These are common needs for manufactures, and RSE has options for a variety of counting systems.

Pill Counter

Pill Counter

The first is to count pharmaceutical or nutraceutical products into a primary package. These automatic counting machines are often referred to as a pill counter, tablet counter, capsule counter or gummy counter. There are three subsets of these types of Nutra and Pharma of counters. They all count pills, tablets, capsules and soft gels into different types of packages. Bottles and jars are most common but pouches, cans and master cases are sometimes used as the package. Semi automatic table top counters are used in small labs while fully a fully automatic pill counting systems will handle the entire packaging process.

The first type of pill counter is the plate counter. These are great for small and medium sized nutraceutical companies. They are inexpensive, flexible and accurate but not very fast. They are not optimal for gummies and odd shaped tablets. The product is metered onto a spinning plate and moves to the perimeter of the plate creating a single file of product. The pieces are guided down a chute and past a sensor which counts them. As they travel a gate stops the flow into the package at the appropriate count. As the next container indexes into position the gate opens and the counting resumes.

Electronic counters are the most popular, and they come in a variety of sizes. They are faster, more flexible, while maintaining accuracy. They can be ‘stacked’ on a packaging line when the demand goes up. They are more expensive than plate counters but well suited for most nutraceutical and pharmaceutical companies. They work on all product types and give better performance on gummies than the other types of counters. but not all perform the same. There have been some recent developments in electronic counters that can generate up to 200 containers per minute. The product feeds from a hopper down a number of lanes. Each lane has a sensor which counts and totals the number of pieces at each. The PLC determines what combination of lanes will make the appropriate count and they drop into the container. Gates hold additional product until next container indexes into position. Sinse machine uses multiple lanes and sensors, the process is faster than the single lane counter.

Slat counters are the fastest counters and can generate hundreds of containers per minute. However, they are much more expensive and not very flexible. They require watching to assure consistent accurate counts. These are designed for high speed production with minimal product change overs. The product fills the cavities across a belt and the belt indexes multiple pieces quickly as the belt travels. Product missing a cavity in the belt can cause a miscount.

RSE has solutions for all of these machines as well as the entire turn key packaging automation line.

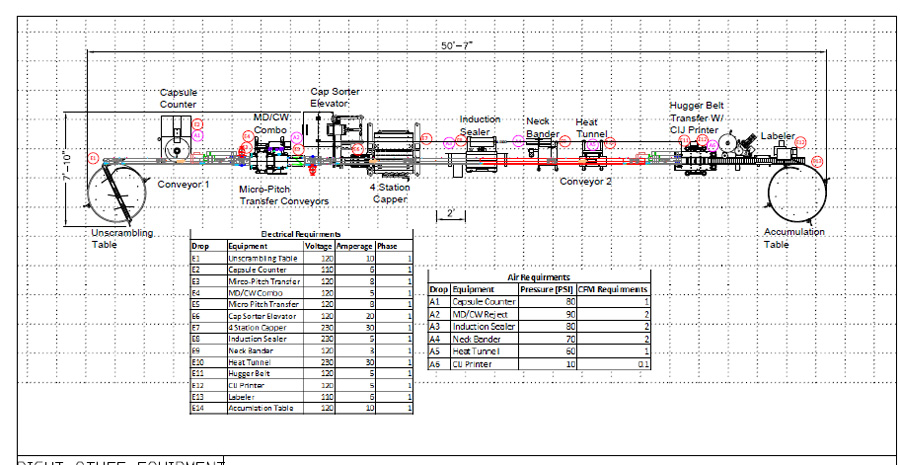

Typical Line Layout

Considering your options for scaling systems? Contact RSE at 303.327.4704, or Email Us for more information.