Right Stuff Equipment (RSE) represents Fanuc Robotics equipment for all of our robotic automation projects.

Call us at 303-327-4704 or email at sales@rightstuffequipment.com to get more information.

Right Stuff Equipment (RSE) represents Fanuc Robotics equipment for all of our robotic automation projects.

Call us at 303-327-4704 or email at sales@rightstuffequipment.com to get more information.

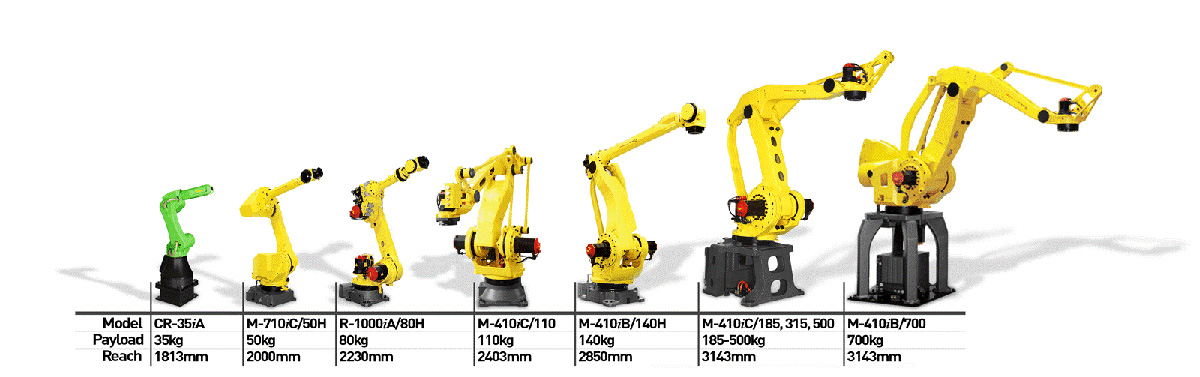

FANUC has the robot model to perform virtually any robotic automation project. RSE is an Authorized Service Integrator (ASI) for Fanuc and we can help you navigate the many robot and end of arm tool (EOAT) options to find the right solution for your robotic automation needs. With more than 100 robot models and infinite EOAT combinations, we will team up for any manufacturing challenge in many industries. FANUC robots are easy to operate and provide complete flexibility thanks to a range of application-specific options and our straightforward integration process.

With payloads from ounces to tons robots are being used in applications from picking and placing candies to automobile assembly. See the summary of robot types below and their many uses. Then reach out to RSE and we will help you define the system and integrate, install and commission the system for you.

Fanuc Industrial (Yellow) Robots perform repetitive motion activities in your facility.

Examples: Palletizing, industrial products, food contact packaging, case packing.

Robot arms play a crucial role in both food processing and industrial facilities by automating tasks that require precision, speed, and consistency. These functions improve efficiency, hygiene, safety, and productivity, making robotic arms essential in modern food production and industrial manufacturing.

Some of their applications include:

Contact RSE to configure the right robot, tool and guarding for your application.

Collaborative robots (Cobots) are designed to work safely alongside human workers, enhancing productivity while ensuring flexibility in various tasks. Unlike traditional industrial robots that require safety cages, cobots have built-in sensors and force-limiting features to prevent accidents, making them ideal for food and industrial applications.

Enhance Productivity – Assist human workers in repetitive or physically demanding tasks.

Improve Safety – Work safely with humans without requiring cages or barriers.

Ensure Consistency – Deliver precise and uniform results in manufacturing and food processing.

Increase Flexibility – Easily reprogrammed for different tasks, making them ideal for dynamic environments.

Reduce Labor Costs – Automate tasks without replacing human workers entirely.

Safer for Human Interaction – Work alongside people without safety barriers.

Easy to Program – Can be taught new tasks with minimal training.

Flexible and Adaptable – Easily redeployed for different jobs.

Improve Worker Ergonomics – Reduce strain from repetitive tasks.

Cost-Effective – More affordable than traditional industrial robots.

Cobots are transforming both food and industrial manufacturing by enhancing efficiency, improving safety, and enabling greater flexibility in production processes.

Contact RSE to configure the right robot, tool and guarding for your application.

Applications of Delta Robots in Food and Industrial Manufacturing

Delta robots are high-speed, parallel-arm robots known for their precision and rapid movement. Their lightweight structure and unique kinematics make them ideal for handling delicate and lightweight items. Here’s where they are commonly used:

High Speed – They operate at extreme speeds, handling hundreds of products per minute.

Precision – Ideal for tasks requiring accuracy, like placing toppings or assembling micro-components.

Hygienic – Often used in food and medical industries due to their clean and controlled operation.

Space Efficient – Their overhead-mounted design saves space on production floors.

Delta robots are transforming automation in food and industrial manufacturing by increasing efficiency, reducing waste, and improving product quality.

Contact RSE to configure the right robot, tool and guarding for your application.

Uses of SCARA Robots in Food and Industrial Manufacturing

SCARA (Selective Compliance Articulated Robot Arm) robots are known for their speed, precision, and flexibility, making them ideal for repetitive tasks that require controlled lateral movement. Their rigid vertical axis and flexible horizontal motion make them perfect for assembly, handling, and packaging tasks.

High Speed & Accuracy – Faster than traditional robotic arms for lateral movements.

Compact & Space-Saving – Ideal for production lines with limited space.

Strong and Precise Vertical Motion – Perfect for assembly and delicate product handling.

Cost-Effective – More affordable compared to six-axis robotic arms.

SCARA robots are widely used in food production, electronics, pharmaceuticals, and automotive industries, boosting efficiency, reducing errors, and improving product quality.

Contact RSE to configure the right robot, tool and guarding for your application.

Right Stuff Equipment sells and services Fanuc Equipment.

We also build complete case packing systems.

Want to learn more about Right Stuff Equipment? Contact Right Stuff Equipment at 303.327.4704, or Email Us.