Right Stuff Equipment (RSE) represents APM sealing equipment exclusively in the Colorado and Wyoming territory. RSE sells, installs and services the full line of band sealing equipment that APM produces. Being local to you means we can deliver savings on the set up and provide quick response-time for service. We also stock parts for the APM product line for customers in our territory.

APM

All Packaging Machinery (APM) has been serving the Packaging Industry for over 70 years and prides itself in the fact that its machines are designed for durability, flexibility and simplicity of operation. Over 50,000 machines have been throughout the Packaging Industry to date.

Currently APM manufactures a full line of bag loading, heat sealing and band sealing machines. Band Sealer models include validation models for use in sealing Medical Pouches. USDA approved baggers and sealers are also available.

Practically any item that can be put in a plastic bag can utilize a bagger or sealer. Applications include the packaging of Food items, Garments, Plastic Parts, Stationery, Bakery, Toys, Pet Products, Decorative, Mailroom, Automotive, Medical Devices, Candy, etc.

Call us at 303-327-4704 or email at sales@rightstuffequipment.com to get more information.

Table Top Band Sealers

APM Model TBS

Application

Products: Pouches

Materials: Polyethylene, Polypropylene, Tyvek®, Foil, Nylon, Co-extrusions, poly-laminates and poly-coated paper materials

Compact and portable USDA approved. This table top model rotary band sealer is for lightweight products only. Pouches over 1 pound should be supported with the TCBS. The TBS can be tilted on a 45 degree angle for easy product handling. Renders a 3/8” wide hermetic seal Models are available with a single line embossing coder for product marking. Validation models are also offered.

Table Top Band Sealers

APM Model TCBS

Tabletop conveyorized vertical rotary sealing system

Features

- The TCBSDM-3/8 has become a very popular machine. The tabletop conveyorized band sealing system with synchronized lower support conveyor and crank handle head height adjustment.

- 3/8″ wide hermetic seal with optional 7/8” seal.

- Synchronized lower support conveyor makes pouch loading easy. Speeds up to 35 feet per minute with synchronous motor drive package.

- Digital precise temperature controller maintains heat up to 450 degrees +/2 degrees.

- Chrome plated sealing assembly followed by cooling section.

- No compressed air required, 110 V, 1 phase, 60 cycle.

- Stainless Steel shafting throughout.

- Smokeless and Odorless sealing.

- Unit designed with all stainless steel covers.

- Embossing coder available as an option.

- Optional Roller In-feed Conveyor for easy product loading is available upon request.

- Optional Casters for easy positioning are available upon request.

- Optional Embossing Coder or Hot Ink printer for product marking is available upon request.

- Options for Standup Pouches with zippers available

Stand Alone Band Sealers

APM Model VCBSDM

Application

Products: Pouches

Materials: Polyethylene, Polypropylene, Tyvek®, Foil, Nylon, Co-extrusions, poly-laminates and poly-coated paper materials

USDA approved Vertical Rotary Band Sealing System with Lower Carry Synchronized Conveyor

Features

- Supplied with Lower Carry Belts and interfaced Variable Speed Conveyor, 6” wide x 5’ long, with fully adjustable stainless steel Guide Rails. Adjustable height Sealing Assembly Floor Stand with crank handle is now standard.

- This continuous band sealer will seal

- Variable speeds up to 540 inches per minute (45 fpm) with dual 3 phase inverter motor drive. Faster versions available.

- Quality hermetic seals of 3/8” wide are standard; 1/4” or 1/8” wide are available. Seals are made by the use of special heavy duty wear-resistant laminated Teflon bands.

- Digital Temperature Control with PID Autotune maintains consistent heat and assures consistently hermetic seals.

- Unit is designed with 5” long heating zone and 5” long cooling zone for greater flexibility in product sealing of difficult materials with temperatures up to 450 degrees Fahrenheit.

- Hard Chrome plated sealing bars followed by Nickel plated cooling bars allow for maximum wear resistance.

- Electrical 110 VAC 10 amps/ 60 Cycle. No compressed air required.

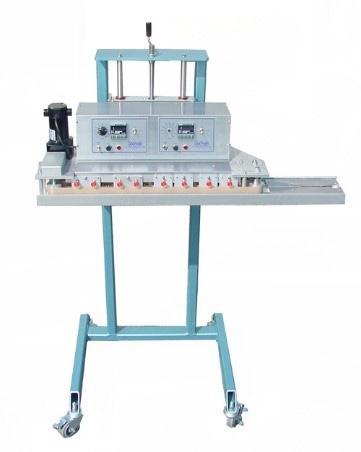

Stand Alone Band Sealers

APM Model VBS DH

Continuous band sealing of medium to heavy duty applications for difficult to seal pouch/bag materials.

Features

- Unit is designed with two 5” heating sections (10” total) and two 5” cooling sections (10” total) for greater flexibility in product sealing of difficult materials with temperatures up to 450 degrees +/- 2 degrees Fahrenheit.

- Designed to seal Kraft/PE, Nylon, Polyethylene, Polypropylene, Laminates, Tyvek / Polymylar and Foil.

- Extra sealing capacity allows speeds up to 60’ per minute with constant secure seals of 1/8”, ¼” or 3/8” wide without bag top trimmer.

- USDA Approved rotary sealing system.

- No compressed air required, 110V, 1 Phase, 60 Cycle.

Medical Band Sealers

Application

Products: Pouches

Materials: Tyvek®, Foil, Nylon, Co-extrusions

APM manufactures quality medical pouch sealers. These continuous rotary band sealers are used to seal Tyvek pouches, foil and other material at high speeds. Validation models are supplied with verification ports. Table top band sealers are also available.

SEALS TYVEK AT 40 FEET PER MINUTE!!

Want to learn more about Right Stuff Equipment? Contact Right Stuff Equipment at 303.327.4704, or Email Us.