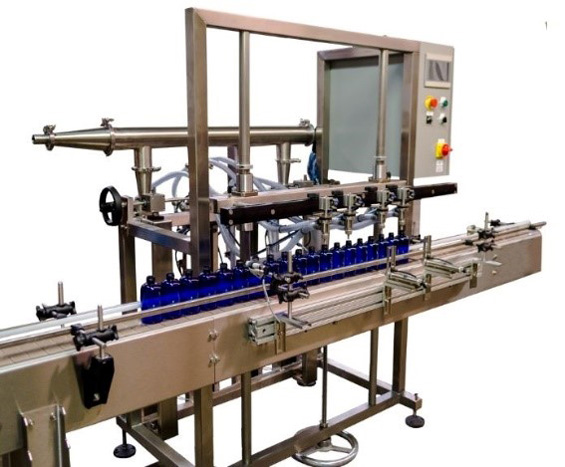

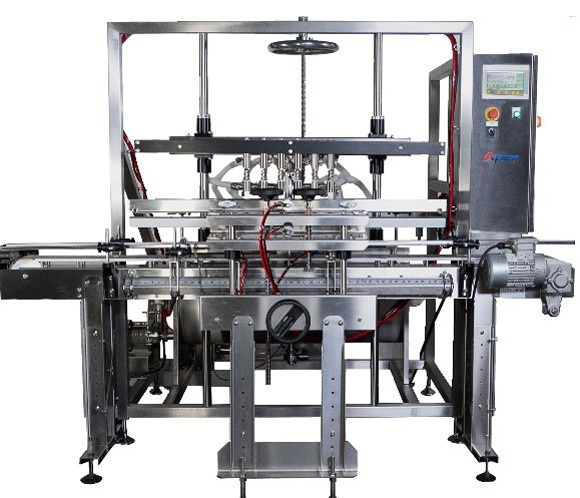

Piston Fillers

Application

Products: Water thin liquids to pastes.

Materials: Jars, bottles, tubs

A piston filler is a type of equipment used for accurately dispensing and filling liquids into containers. It is widely employed in industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals. This type of filler operates based on a piston-and-cylinder mechanism to draw in and dispense precise volumes of liquid.

Key Features and Components

- Piston and Cylinder System: The central mechanism consists of a piston inside a cylinder. As the piston moves back and forth, it creates suction to pull liquid into the cylinder and then forces the liquid out for filling.

- Nozzle: A delivery nozzle ensures the liquid is directed precisely into the container. Anti-drip mechanisms are often included to prevent spillage and maintain cleanliness.

- Control Valves: These direct the liquid flow between the liquid source and the filling nozzle, synchronizing with the piston movement. Rotary valves can be employed for liquid with particulates.

- Adjustment Options: Volume adjustments allow the user to control the amount of liquid dispensed per stroke, making it suitable for a wide range of container sizes.

- Construction Materials: Depending on the application, the filler is made of stainless steel or other corrosion-resistant materials to maintain hygiene and durability.

How It Works

- Filling Phase: As the piston moves back, it creates a vacuum that draws liquid from a supply tank into the cylinder.

- Dispensing Phase: When the piston moves forward, the liquid is forced out of the cylinder and through the nozzle into the container.

Applications

- Food and Beverage: Filling sauces, syrups, oils, and beverages.

- Pharmaceuticals: Dispensing medicines, syrups, and sterile liquids.

- Cosmetics: Filling lotions, shampoos, creams, and gels.

- Chemical: Packaging solvents, detergents, or other liquid chemicals.

Advantages

- High accuracy and consistency in filling.

- Versatile for different liquid viscosities, from thin liquids to thick pastes.

- Easy to clean and maintain, especially in sterile environments.

- Simple operation and durable design.

Variants

Some liquid piston fillers are manual, while others are semi-automatic or fully automatic, depending on production needs. They may also integrate with larger production lines for high-speed filling.