When making decisions on how to move products through a production line process using conveyor systems, there are ten recommendations to consider before you make a purchase. Here are 10 tips on how to buy the right conveyor system.

Ten Tips For Buying Packaging Conveyor Systems for Food, Beverage & Supplement Manufacturing Environments

Tip 1: Understand Your Products

- Compile Product Dimensions: The dimension of the products you will be conveying are important. Compile all the lengths, widths and heights of products before contacting the potential suppliers.

- Assess Product Weight or Density: Weight packages and density of raw material will have an impact on the load calculations for the conveyor. Understand the weight and density of your product as well as how much stuff will be on the conveyor at any point in time.

- Assess Throughput: The amount of product being presented to the conveyor system will be another important piece of information to calculate the anticipated load on the conveyor. This will determine the belting options, gear ratio, and horsepower required for the motor.

Tip 2: Assess the Production Environment

The environment will sometime dictate the materials of construction in the conveyor system’s frame, belting, and motors. Ignoring the environmental aspect can result in a line that wears badly or could even be extremely dangerous. Typical Food and beverage concerns include

- Dry, wipe down

- Wet wash-down

- USDA

- Dairy 3A

- Refrigeration or below freezing

- Explosive

Tip 3: Consider the Transfers On & Off The Conveyor

In many production lines, there are machines that come with their own conveyor. That means you are stitching your new conveyor systems together with these machines. Typical examples of machines that come with their own conveyors include: metal detectors, cappers, sleevers, labelers, and more. Your product will transfer on and off these other conveyors. There are a variety of ways to handle transfers but knowing all the details about these other machines and their conveyors, as well as the product dimensions mentioned above, will help determine what you should buy.

Tip 4: Determine What Types of Controls You Want

- On/Off: Simplest and lowest cost.

- VFD: Allows you to increase or decrease conveyor speed. Critical in some applications

- PLC: PLC controls can allow machines in your line to communicate with each other and the conveyor improving efficiency and reducing down time

- Extra E- Stops: Improves safety by allowing the conveyor to be shut down from multiple locations on the line

Tip 5: Understand OEE (Overall Equipment Efficiency)

This is a measure for how much of the time your machine or line actually produces product.

Tip 6: Consider a Preventive Maintenance Program

If you don’t have a strong culture of Preventive Maintenance, then consider a PM program from a technical support provider. It can keep your conveyor systems running better and save you money by keeping your equipment up and running for the long term.

Tip 7: Utilities demand

Know what power and air supply you have in the building, including voltage. The most common types of power required with this type of equipment are: 120, single phase, 220 single phase, 230 three phase, and 480 three phase.

Tip 8: Consider Employee Safety Requirements

To assure employee safety, make sure you understand where workers will be positioned on the conveyor line and what they will be doing. Consider and buy for the following employee safety considerations:

- Lifting and repetitive motion

- Guarding

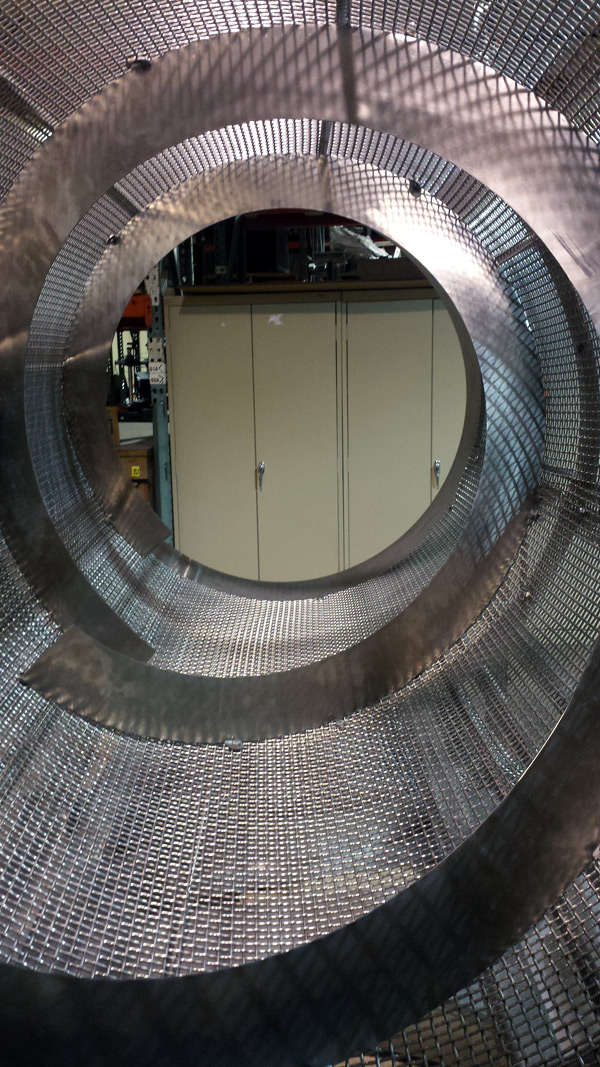

Tip 9: Consider How You Move powder, granular, coffee & similar products

These types of products often are moved from one point to another in the plant for packaging. There are a few typical ways to move these products. Understanding the options will help you decide what’s best for your production.

- Drag: A chain or cable moves through a tube and disks attached pull and push product through the tube to the final discharge point(s). Gentle, capable of long distance transport, multiple inputs and discharge points are possible. This option is expensive.

- Pneumatic: Typically, a vacuum pulls product from a hopper and delivers it to a feeder. This option is inexpensive, easy to clean, covers shorter distances, and limits bulk densities.

- Screw or Auger: An auger or flexible screw will run within a tube and move the product by rotating. These systems often are used to convey material from a hopper up to a feeder over a bagger. This option is inexpensive, flexible, and can be easy to clean, but there are limits to the distance of conveyance.

Tip 10: Consider Buying Conveyor Systems Through an Integrator

Packaging line integrators with experience will know more about these criteria than written here and help you design and install the complete conveyor system. The system often involves multiple conveyors integrating with the machines mentioned that have their conveyance. The goal is a balanced line that moves product smoothly through the entire system at the required rates and meets your production needs.

When buying packaging conveyor systems, there are other factors to consider based on a case-by-case basis. If you need some help researching and buying conveyor systems, call Right Stuff Equipment in Denver, Colorado USA at 303.327.4704, or Email Us.